3-D Engineering

WORLD Class engineering and manufacturing Services Company

We design and produce innovative equipment and products on behalf of our clients.

Our team at 3-D Engineering is success driven with a proven track record offering world-class engineering services. We are the preferred partner of those companies looking to outsource the design development and/or manufacturing of their products. We provide a full spectrum of engineering and manufacturing services throughout the development process starting with concept development through production and support.

Our integrated capability consisting of multi-disciplinary engineering expertise, technical knowledge and experience, along with our contract manufacturing capability and industry partnerships allows us to quickly and efficiently mobilize the right resources and skill sets for the specific needs of our clients. We work closely with our clients in a collaborative approach to ensure achievement of client’s goals.

Our team consists of a multidisciplinary group of experienced and highly skilled and dedicated engineers.

Systems Engineering

Systems engineering is of paramount importance in insuring the development of successful innovative products. Too often this role is not executed well and poor results are realized. At 3-D Engineering we work hard to understand complex problems by utilizing methods to help visualize and quantify the solution. Examples are Functional Flow Block Diagrams, Data Flow Diagrams and Sequence Diagrams to graphically represent various subsystems and components.

Once the requirements are understood, it is the responsibility of the systems engineer to refine them, and to determine, along with other engineers, the best technology for a job. To accomplish this task may involve trade studies and a decision matrix or the Pugh method be employed. This process is iterative and provides a method to quickly converge on optimum solutions. The decision matrix is populated using techniques such as statistical analysis, reliability analysis, system dynamics, and optimization methods.

The system engineer develops design requirements based on functional requirements. Feasible solutions along with a sufficient set of constraints are generated and refined to produce an optimal solution. 3-D Engineering is well versed in the methods and modeling techniques that produce low cost and highly reliable products. Let us help you with your design requirements, technology assessments, feasibility studies and concept development/validations.

Our System Engineering capabilities include these and various other services..

Electrical Systems:

Industrial Industrial PLC’s:

Product technologies:

SOFTWARE Engineering

Application Development:

Hardware Development:

Development Tools

Design experience includes digital, analog, d/a and a/d circuits, FPGA design, I/O processing, interface to sensors of all types, board layout, electro-optical and electro-mechanical designs. We work with all industrial wiring specs and International and NRTL listing and filing requirements, as well as FDA, Semi S2, CE.

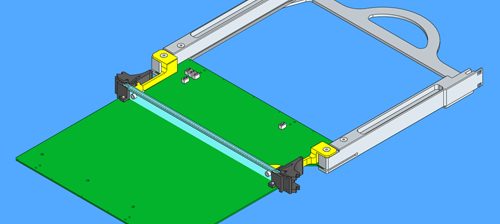

Mechanical Engineering

Mechanical Design

Standards

Tools and Software

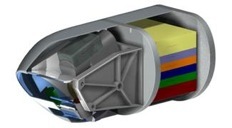

Optical Engineering

If you do not specifically see what you are looking for – contact us.

Analysis

CALL US TODAY

3-D Engineering Corporation

Our Services