Prototyping

3-D Engineering

WORLD Class engineering and manufacturing Services Company

We design and produce innovative equipment and products on behalf of our clients.

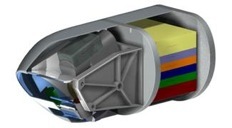

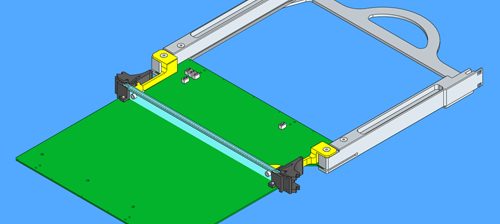

Extensive use of prototyping is part of our product development. Prototyping techniques include: 3-D solid modeling for virtual prototyping; Fabrication and procurement of parts for production of prototypes. Prototypes are full working models, suitable for design verification, product validation, and industry certification.

3-D Engineering Corporation

Our Services

1-951-296-3060